Nitrile o-rings, also known as Buna-N o-rings or NBR o-rings, are one of the most common types of o-ring materials because of their low-cost performance in basic water, oils, fuels, and lubricants.

For general purpose applications such as pneumatics, hydraulics, and fuel systems, Nitrile o-rings provide cost-effective sealing performance, especially when hydrogenated versions or specialty material compounds are used. Nitrile o-rings are not recommended for exposure to outdoor weathering or harsh chemical environments.

Nitrile o-rings from allorings.com are in-stock and ready to ship today. Order online today from the world's largest o-ring inventory network for fast shipping and reliable service.

Service Temperature Range |

Resistances |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Temp. Range, °F | Abbv. | High Temp. Range, °F | Compr. Set | Oils | Steam | Weather/ UV |

Fuels | Acids/ Solvents |

Bases | Abrasion Wear | Permeation |

|

|

|

|

|

|

|

|

|

|

||

|

|

||||||||||

Order Online

Click CPD# Button

Order Online

Click CPD# Button

Popular Allorings Compounds |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compound | Relative Price |

Relative Availability |

Low Temp ° F | High Temp ° F | Durometer | Color | Special Features |

||||||

|

B1000

View DatasheetQuote or Order Online

|

|

|

-30 | 250 | 70 | Black |

|

||||||

|

B1001

View DatasheetQuote or Order Online

|

|

|

-30 | 250 | 90 | Black |

|

||||||

|

B1002

View DatasheetQuote or Order Online

|

|

|

-30 | 250 | 70 | Black |

FDA

Food contact grade compound. FDA compliant.

|

||||||

|

B1006

Quote or Order Online

|

|

|

-30 | 250 | 50 | Black |

|

||||||

|

B1125

Quote or Order Online

|

|

|

-65 | 250 | 70 | Black |

|

||||||

|

Quote

Quote

|

Need a compound not shown here or not sure what is best for your application? Click the QUOTE button to describe your situation and we will respond quickly. |

||||||||||||

General Description:

Nitrile, also commonly referred to as Buna-N or NBR, is a copolymer of Acrylonitrile and Butadiene. Nitrile is the most commonly used elastomeric material for molded and extruded products. This material offers relative low cost, good mechanical properties, and resistance to many common oils, fuels and lubricants. NBR has poor resistance to weathering, sunlight and ozone so it is best used in enclosed environments where parts are not exposed to the elements. Hydrogenated versions of NBR (HNBR) have enhanced mechanical properties as well as greater thermal and chemical stability. Specific physical properties and chemical resistances vary by compound formulation.

NBR can be compounded for enhanced oil and fuel resistance, increased temperature flexibility, high hardness and extrusion resistance, low compression set, and a variety of other attributes. The physical properties of the compound largely depend on the Acrylonitrile content of the formulation. For example, high Acrylonitrile content causes increased oil and fuel resistance while adversely affecting low temperature flexibility and compression set resistance. It is important to consider the offsetting attributes when selecting an NBR formulation. Please contact a Marco Rubber engineer for assistance finding the best compound for your application.

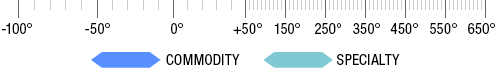

Service Temperature Range*

–31°F (–35°C) to 230°F (110°C)

Specialty formulations, Low Temperature: –76°F (–60°C)

Specialty formulations, High Temperature: 275°F (135°C).

*Approximation for dry air service. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. Consult a Marco Engineer for more details.

Typical Applications and Products:

The range of performance characteristics of Nitrile allows it to be utilized in a diverse set of applications. NBR is often used for gaskets and o-rings in pneumatic, hydraulic, and fuel systems. V-packings and backup rings made from high-hardness Nitrile compounds are common in high pressure environments in the Oil and Gas industry. The abrasion and wear resistance of NBR make it useful for dynamic oil seals for rotary and reciprocating shafts. NBR is relatively easy to process which keeps costs down for custom extrusions and complex molds. Hardness ranges from 40 Shore A to 90 Shore A.

Chemical resistance:

- Petroleum greases, mineral oils, vegetable oils

- Aliphatic hydrocarbons

- Hydraulic fluids (HFA, HFB, HFC types)

- Limited resistance to dilute acids, alkalis, and solvents

Not compatible with:

- Highly Aromatic fuels and hydrocarbons

- Weathering, sunlight and ozone

- Chlorinated hydrocarbons

- Polar solvents

- Glycol brake fluids