Buy Viton® o-rings quick and easy from the world’s largest Viton® o-ring inventory network.

Viton® o-rings offer excellent chemical and temperature resistance and are available in a wide variety of FKM types and formulations. Standard AS568 imperial, metric and non-standard Viton® o-ring sizes are kept in stock, and custom Viton® o-rings are typically available with no tooling fees and rush deliviers.

Specialty FPM and FKM compounds are available for improved low temperature and chemical resistance. Viton® specialty formulations are also available for durometer hardness, colors, food and medical grade, high pressure, and explosive decompression resistance. Viton® fluorocarbon compounds are widely used in chemical, aerospace and industrial applications, but are not recommended for use with steam, amines, or polar solvents.

Service Temperature Range |

Resistances |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Temp. Range, °F | Abbv. | High Temp. Range, °F | Compr. Set | Oils | Steam | Weather/ UV |

Fuels | Acids/ Solvents |

Bases | Abrasion Wear | Permeation |

|

|

|

|

|

|

|

|

|

|

||

|

|

||||||||||

Order Online

Click CPD# Button

Order Online

Click CPD# Button

Popular Allorings Compounds |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compound | FKM Type | Relative Price |

Relative Availability |

Low Temp ° F | High Temp ° F | Durometer | Color | Special Features |

|||||

|

V1000

View DatasheetQuote or Order Online

|

A |  |

|

-15 | 437 | 75 | Black |

|

|||||

|

V1003

View DatasheetQuote or Order Online

|

A |  |

|

-15 | 437 | 75 | Brown |

|

|||||

|

V1007

View DatasheetQuote or Order Online

|

A |  |

|

-15 | 437 | 90 | Black |

|

|||||

|

V1020

View DatasheetQuote or Order Online

|

ETP |  |

|

-6 | 437 | 75 | Black |

|

|||||

|

V1038

View DatasheetQuote or Order Online

|

GLT |  |

|

-40 | 437 | 75 | Black |

|

|||||

|

V1090

View DatasheetQuote or Order Online

|

GLT |  |

|

-40 | 437 | 90 | Black |

NORSOK

NACE

GLT type compound with improved low temperature resistance, higher hardness, and Explosive Decompression (ED) resistance. Excellent for oilfiled and drilling applications.

|

|||||

|

Quote

Quote

|

Need a compound not shown here or not sure what is best for your application? Click the QUOTE button to describe your situation and we will respond quickly. |

||||||||||||

Why Buy Viton O-Rings?

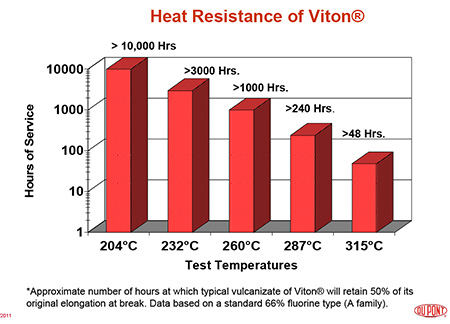

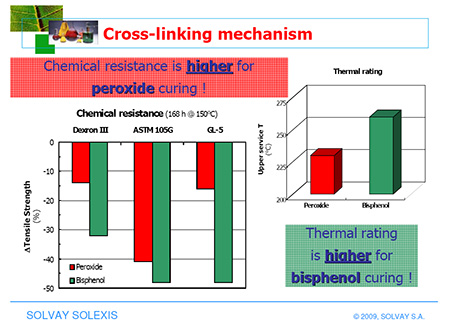

Viton® O-Ring and seal performance cost benefit makes it the second most popular sealing material. Fluoroelastomer (Viton®, FKM) offers a wide range of resistance to chemicals, oil and heat, with situational service life above 200°C. The outstanding heat stability and excellent resistances are due to the high ratio of fluorine to hydrogen, the strength of the carbon-fluorine bond, and the absence of unsaturation. FKM compounds are widely used in chemical, automotive, aerospace and industrial applications. Fluoroelastomers are referred to generically as FKM polymers per the nomenclature noted in ASTM D1418. In the SAE J200 ASTM D2000 classification system for rubber materials Fluoroelastomers are documented as a “HK”.

Common Viton® Names:

FKM, FPM (Europe), Fluoropolymer, Fluoroelastomer.

Viton® Trade Names:

Viton®, Fluorel®, Technoflon®, Dai-El®.

Specialty Performance Polymer Types:

A, B, F, GLT, GFLT, XLT, ULT, ETP, TBR.

Features Of Viton® O-Rings:

- Situational service life above 200°C

- Excellent resistance to acids, fuels, mineral and vegetable oils and greases, aliphatic, aromatic and chlorinated hydrocarbons, non-flammable hydraulic fluids (HFD) and many organic solvents and chemicals.

- Excellent resistance to aging and ozone.

- Low gas permeability, low compression set.

Limitations of Viton® O-Rings:

- Ketones (MEK,and Acetone) and Skydrol fluids.

- Amines and Anhydrous Ammonia.

- Low molecular weight esters and ethers. Hot hydrofluoric or chlorosulfonic acids and low molecular weight organic acids (formic and acetic acids).

- Polar solvents, low molecular weight organic solvents and glycol-based brake fluids

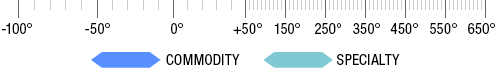

Viton® Seal Temperature Range*:

-17°F (-27°C) to 437o F (225°C)

Specialty formulations, Low Temperature: -67°F (-55°C)

Specialty formulations, High Temperature: 450°F (232°C)

*Approximation for dry air service. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. Consult a Marco Engineer for more details.

FKM Type Comparison Chart

FKM Viton® Type |

A |

B |

F |

GF |

GLT |

GFLT |

XLT |

ULT |

ETP |

Aflas® |

BRFKM |

|---|---|---|---|---|---|---|---|---|---|---|---|

Allorings Commodity Compound number |

V1000 |

V1032 |

V1088 |

V1081 |

V1038 |

V1033 |

V1086 |

V1166 |

V1020 |

L1000 |

L1010 |

| Relative Pricing |  |

|

|

|

|

|

|

|

|

|

|

| Availability |  |

|

|

|

|

|

|

|

|

|

|

H2S % |

2 |

5 |

5 |

5 |

5 |

5 |

10 |

10 | 5 |

20 |

40 |

High Temperature Performance F° (C°) |

437 (225) | 437 (225) | 437 (225) | 437 (225) | 437 (225) | 437 (225) | 437 (225) | 437 (225) | 437 (225) | 450 (232) | 450 (232) |

Low Temperature Performance F° (C°) |

-17 (-27) | -11 (-24) | 1 (-17) | 3 (-16) | -40 (-40) | -29 (-34) | -58 (-50) | -67 (-55) | -6 (-21) | 19(-7) | 1(-17) |

| TR-10 Low Temperature Flexibility F° (C°) | 1 (-17) | 7 (-14) | 20 (-7) | 21 (-6) | -22 (-30) | -11 (-24) | -40 (-40) | -49 (-45) | 12 (-11) | 37 (3) | 20 (-7) |

| Strong Base, high pH, Caustic, Amines | |||||||||||

| Low Molecular Weight Carbonyls 100% concentration (MTBB, MBK, MIBK, etc.) |

|||||||||||

| Engine Lubricating Oil, SG and SH | |||||||||||

| Aqueous fluids, steam, mineral acids (H2So4, HNO2) |

|||||||||||

| Aromatic Hydrocarbons (toluene, etc.) | |||||||||||

| Automotive Fuels Oxygenated with MEOH, ETOH, MTBE, etc. |

|||||||||||

| Engine Lubricating Oil, SE and SF | |||||||||||

| Resistance to Compression Set | |||||||||||

| Automotive and Most Aviation Fuels |

| Rating Scale: | = Excellent | = Good | = Not Recommended |