EPDM o-rings deliver excellent chemical and thermal resistance at a low price point. EPDM o-ring materials are used in a wide range of water and irrigation applications. EPDM o-rings are not recommended for exposure to most oils.

EPDM o-rings from allorings.com are in-stock and ready to ship today. Order online from the world's largest o-ring inventory network for fast shipping and competitive pricing.

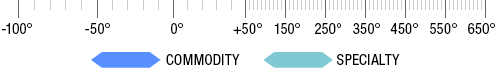

Service Temperature Range |

Resistances |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Temp. Range, °F | Abbv. | High Temp. Range, °F | Compr. Set | Oils | Steam | Weather/ UV |

Fuels | Acids/ Solvents |

Bases | Abrasion Wear | Permeation |

|

|

|

|

|

|

|

|

|

|

||

|

|

||||||||||

Order Online

Click CPD# Button

Order Online

Click CPD# Button

Popular Allorings Compounds |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compound | Relative Price |

Relative Availability |

Low Temp ° F | High Temp ° F | Durometer | Color | Special Features |

||||||

|

E1000

View DatasheetQuote or Order Online

|

|

|

-65 | 300 | 70 | Black |

FDA

NSF61

Food, beverage, and drinking water grade compound. FDA and NSF-61 compliant.

|

||||||

|

E1055

View DatasheetQuote or Order Online

|

|

|

-65 | 300 | 70 | Black |

|

||||||

|

Quote

Quote

|

Need a compound not shown here or not sure what is best for your application? Click the QUOTE button to describe your situation and we will respond quickly. |

||||||||||||

General Description:

Ethylene-Propylene based elastomers make up a family of synthetic rubbers characterized by excellent chemical and thermal resistance. These materials can be compounded in a variety of ways for use in a wide range of demanding applications. Ethylene-Propylene elastomers are most commonly available as EPR, a copolymer of ethylene and propylene, and EPDM, a terpolymer. EPR and EPDM have very similar properties and the abbreviations are often used interchangeably. EPDM can be cured with either Sulphur or Peroxide. Sulphur curing is less expensive and easier to process but the product may be tacky and can exhibit some bloom. Peroxide curing is more difficult to process but provides better chemical, thermal, and aging resistance.

Service Temperature Range*:

-65°F (–54°C) to 300°F (149°C)

*Approximation for dry air service. Actual temperature range of a compound in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and thermal cycling effects, and other factors. Consult a Marco Engineer for more details.

Typical Applications and Products:

EPDM is a versatile and relatively inexpensive material. It is often used in drinking water systems (NSF61, KTW, WRC/WRAS) due to its Chlorine and Chloramine resistance and in hydraulic and braking systems due to its excellent Glycol resistance. Other common uses include Medical and Pharmaceutical (USP class VI and ISO 10993) applications and Food and Dairy applications (NSF51 and USDA 3A). EPDM is available in o-rings, sheets, gaskets, custom molded products or extruded as solid or sponge. Hardness ranges from 40 Shore A to 90 Shore A. Special grades with military approvals are also available. EPDM has poor resistance and should not be used with most petroleum and mineral oil products. Specialty formulations with Y267 (L’Garde) cure are used in high temperature and pressure steam environments in geothermal applications.

Chemical resistance:

- Hot water and steam up to 300°F (149°C) with special compounds up to 600°F (315°C)

- Glycol based brake fluids up to 300°F (149°C)

- Many organic and inorganic acids

- Cleaning agents, soda and potassium alkalis

- Phosphate-ester based hydraulic fluids (HFD-R)

- Silicone oil and grease

- Many polar solvents (alcohols, ketones, esters)

- Ozone, aging and weather resistant

Not compatible with:

- Petroleum and mineral oil products (oils, greases and fuels)