Silicone o-rings are excellent seal materials for static, high temperature applications. Featuring outstanding flex and fatigue life, ozone and UV radiation resistance, physiologically neutral and insulating properties, silicone o-rings are effective in a wide range of applications. Find the silicon o-ring compound property that's perfect for you in the chart below, then easily order online from the world's largest silicone o-ring inventory network.

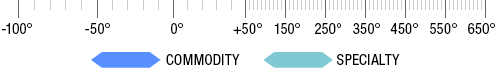

Silicone O-Ring Temperature and Resistance Chart

Service Temperature Range |

Resistances |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Temp. Range, °F | Abbv. | High Temp. Range, °F | Compr. Set | Oils | Steam | Weather/ UV |

Fuels | Acids/ Solvents |

Bases | Abrasion Wear | Permeation |

|

|

|

|

|

|

|

|

|

|

||

|

|

||||||||||

Order Online

Click CPD# Button

Order Online

Click CPD# Button

Popular Allorings Compounds |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compound | Relative Price |

Relative Availability |

Low Temp ° F | High Temp ° F | Durometer | Color | Special Features |

||||||

|

S1000

View DatasheetQuote or Order Online

|

|

|

-75 | 400 | 70 | Orange |

FDA

Food and beverage grade compound. FDA compliant.

|

||||||

|

S1005

Quote or Order Online

|

|

|

-75 | 400 | 50 | Orange |

|

||||||

|

S1015

Quote or Order Online

|

|

|

-65 | 500 | 70 | Orange |

|

||||||

|

S1037

View DatasheetQuote or Order Online

|

|

|

-65 | 400 | 70 | Clear-Translucent |

FDA

USP

Ultra clean compound for use in medical and pharmaceutical applications. Manufactured and packaged in a clean room.

|

||||||

|

S1043

Quote or Order Online

|

|

|

-100 | 400 | 50 | Orange |

|

||||||

|

S1083

Quote or Order Online

|

|

|

-65 | 400 | 70 | Clear-Translucent |

FDA

USP

Medical and pharmaceutical grade compound. NOT manufactured or packaged in a clean room. For clean room MFG, see S1037.

|

||||||

|

Quote

Quote

|

Need a compound not shown here or not sure what is best for your application? Click the QUOTE button to describe your situation and we will respond quickly. |

||||||||||||

Common Silicone Names:

Silicone, VMQ, PVMQ

Trade Name:

Silastic®, Elastosil®, Thermoflex®

Features:

- Can be compounded to meet FDA, USP Class VI, USDA, 3-A and Canada AG

- Excellent heat and compression resistance, excellent flexibility, good electrical insulator

- Excellent resistance to oxygen, ozone and sunlight, animal and vegetable oil and grease

- Resistance to fungal and biological attack

Limitations:

- Not recommended for dynamic application since it has low strength and poor abrasion resistance & high gas permeability

- Concentrated solvents, oils, concentrated acids, diluted sodium hydroxide, hydrocarbon based fuels, aromatic mineral oil

- Aromatic Hydrocarbons (benzene, toluene), aromatic mineral oil, acids and alkalis, Superheated water or steam over 250 F

Service Temperature:

- -90 to 500° F (-68 to 260° C). Depending on compound and application.