HNBR o-rings are made from hydrogenated nitrile specifically designed to provide superior temperature and fuel resistance compared to traditional NBR materials. HBNR o-rings also feature excellent abrasion, wear, and compression set resistance, making them a reliable o-ring in a wide range of tough applications.

Allorings.com has one of the world's largest inventory networks of HNBR o-rings and extensive network of made on demand manufacturers. Try our easy-to-use online ordering system to order HNBR orings available online and ready to ship today.

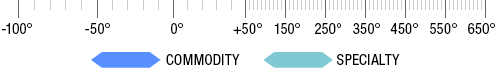

Service Temperature Range |

Resistances |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Temp. Range, °F | Abbv. | High Temp. Range, °F | Compr. Set | Oils | Steam | Weather/ UV |

Fuels | Acids/ Solvents |

Bases | Abrasion Wear | Permeation |

|

|

|

|

|

|

|

|

|

|

||

|

|

||||||||||

Order Online

Click CPD# Button

Order Online

Click CPD# Button

Popular Allorings Compounds |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compound | Relative Price |

Relative Availability |

Low Temp ° F | High Temp ° F | Durometer | Color | Special Features |

||||||

|

R1000

View DatasheetQuote or Order Online

|

|

|

-30 | 325 | 70 | Green |

|

||||||

|

R1001

View DatasheetQuote or Order Online

|

|

|

-30 | 325 | 70 | Black |

|

||||||

|

Quote

Quote

|

Need a compound not shown here or not sure what is best for your application? Click the QUOTE button to describe your situation and we will respond quickly. |

||||||||||||

Common Names:

HNBR (Hydrogenated acrylonitrile butadiene rubber), Hydrogenated Nitrile.

Trade Names:

Therban®, Zetpol®

General Description:

Hydrogenated Nitrile was specifically developed for increased temperature resistance and better compatibility with new automotive fuels. Hydrogenated Nitrile also offers higher strength and minimal degradation at high temperatures. Specific physical and chemical resistances vary by compound formulation.

Features:

- Compatible with Freon R-134a and compressor lubricant oil.

- Extended temperature capabilities.

- Enhanced chemical compatibility with new automotive fuels.

- Good/Excellent resistance to compression set and tear/abrasion.

- Good/Excellent resistance to many petroleum oils/greases, H2S, hydraulic fluids, alcohol, ambient water, silicone greases, Di-ester base lubricants, CO2 and ethylene-glycol based fluids.

Limitations:

- Ozone, direct sunlight, UV, weathering, aromatic fuels, glycol-based brake fluids, polar solvents, non-flammable hydraulic fluids (HFD), aromatic/chlorinated hydrocarbons, ketones, esters, and aldehydes.

Service Temperature:

- -40° to 150° C (-40° to 300° F)